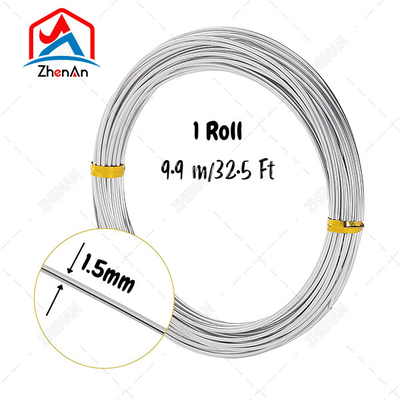

Packaging Machinery Aluminum Sealing Wire, Heat Resistant Coating, Consistent Performance in Automation

What are the uses of aluminum wire?

Aluminum wire is a conductive wire made of aluminum alloy, which has good conductivity, light weight and corrosion resistance. Therefore, it has a wide range of uses in industry, construction, transportation and other fields.

First, in the field of construction, aluminum wire is widely used in the installation of power transmission and distribution lines and internal electrical lines in buildings. Because aluminum wire has good conductivity, it can effectively transmit electric energy, and it is more economical than copper wire. Therefore, in large-scale construction projects, especially in high-rise buildings and large commercial complexes, aluminum wire is widely used in the laying of indoor and outdoor power lines and the construction of power transmission and distribution systems.

Secondly, in the field of transportation, aluminum wire is widely used in the construction of rail transit and urban tram lines. Aluminum wire can meet the high power requirements of tram lines, and its lightweight characteristics also help to reduce the construction cost of tram lines. Therefore, in some cities in developed countries, aluminum wire is widely used in the construction and operation of urban rail transit systems such as subways, light rails, and trams.

In addition, in the industrial field, aluminum wire is also used in the manufacture and maintenance of electrical equipment such as motors and electrical equipment. Because aluminum wire has good conductivity and corrosion resistance, it can meet the requirements of motors and electrical equipment for conductive materials, and in some occasions where lightweight is required, the lightweight characteristics of aluminum wire also have great advantages.

In addition, with the development of renewable energy, aluminum wire is also widely used in the construction of solar power stations and wind farms. In these occasions, aluminum wire can be used as a material for power transmission and distribution lines to effectively transmit the electricity generated by renewable energy.

In summary, aluminum wire has a wide range of uses. It can not only be used in power transmission and distribution systems in the fields of construction, transportation, industry, etc., but also in the utilization of renewable energy. Aluminum wire plays an important role in improving the performance of electrical equipment, reducing construction and operating costs, and promoting the development of renewable energy. Therefore, in the future, the application field of aluminum wire will continue to expand and make greater contributions to the development of various fields.

Specifications

| Al |

Zn |

Mn |

Cu |

Fe |

Si |

Ti |

| ≥99.7 |

≤0.07 |

≤0.05 |

≤0.05 |

≤0.04 |

≤0.03 |

≤0.05 |

| Molecular Weight |

26.98 |

| Appearance |

Silvery |

| Melting Point |

660.37 °C |

| Boiling Point |

2467 °C |

| Density |

2700 kg/m3 |

| Solubility in H2O |

N/A |

| Poisson's Ratio |

0.35 |

| Young's Modulus |

70 GPa |

| Vickers Hardness |

167 MPa |

| Tensile Strength |

6800 psi Coldroled 16,000 psi. |

| Thermal Conductivity |

2.37 W/cm/ K @ 298.2 K |

| Thermal Expansion |

(25 °C) 23.1 µm·m-1·K-1 |

| Electrical Resistivity |

2.6548 microhm-cm @ 0 °C |

| Electronegativity |

1.5 Paulings |

| Specific Heat |

0.215 Cal/g/ K @ 25 °C |

| Heat of Fusion |

2.55 Cal/gm mole |

| Heat of Vaporization |

67.9 K-Cal/gm at om at 765 °C |

Packing & Delivery

Packing: 1 ton big bag, 20-25mt in 20' container

Our Services

We can try our best to provide you the good services as below:

1. We have Experienced staffs .

2. Provide kinds of certificates.

3. 24 hours on line to answer all your questions .

4. The content packing particle size may be based on customer demand.

5. Quality can be guaranteed. we provide safe products to our users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!