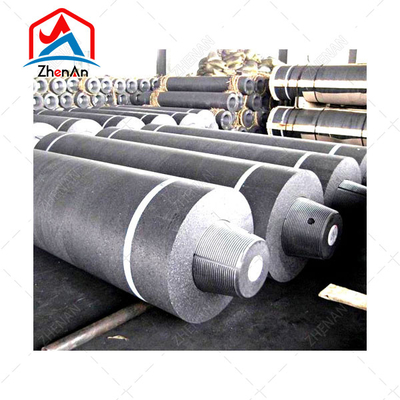

Ef Lf Arc Furnaces Graphite Plate Welding Steeling Making Furnace Smelting Electrode

Why Choose Us

1. Trade Assurance, Quality Guarantee, On-time Delivery, Secure Payment.

2. We supply competitive price,reliable delivery.

3. We accept small order and sample order for trial order.

4. Follow up and feed back tightly during production process.

5. Price term and payment negotiable.

6. We supply outstanding service.

What are the steps in the manufacture of graphite electrodes?

Graphite electrode is an electrode made of graphite as raw material. It has the characteristics of high purity, high density, high strength and high conductivity, and is widely used in many fields.

The manufacturing process of graphite electrodes mainly includes the following steps:

Batch: Mix high-purity graphite powder, binder, conductive agent and other raw materials in a certain proportion.

Kneading: Put the mixed raw materials into a kneading machine, add an appropriate amount of water, and knead into a uniform slurry.

Molding: Put the kneaded slurry into a mold and pressurize it.

Roasting: Put the formed graphite blank into a roasting furnace and roast it at a certain temperature for a certain time to improve its strength and conductivity.

Processing: Process the roasted graphite blank, such as turning, drilling, etc., to obtain the required shape and size.

| UHP Size and Tolerance |

| Diameter (mm) |

Length (mm) |

| Nominal diameter |

Actual diameter |

Nominal length |

Tolerance |

Short feet length |

| mm |

inch |

max |

min |

mm |

mm |

max |

min |

| 200 |

8 |

209 |

203 |

1800/2000/

2200/2300

2400/2700

|

±100

|

-100

|

-275

|

| 250 |

10 |

258 |

252 |

| 300 |

12 |

307 |

302 |

| 350 |

14 |

357 |

352 |

| 400 |

16 |

409 |

403 |

| 450 |

18 |

460 |

454 |

| 500 |

20 |

511 |

505 |

| 550 |

22 |

556 |

553 |

| 600 |

24 |

613 |

607 |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

FAQ

Q: What's your advantage?

A: Honest business with competitive price and professional service on export process.

Q: How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

Q: Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

Q: Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!