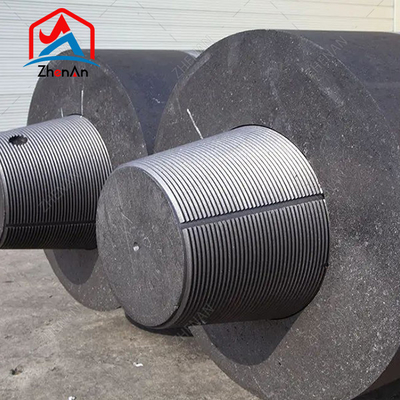

RP HP SHP UHP graphite electrode with nipples Good Conductivity Long Service Life

What we offer

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

Understand the main technical parameters of high-power graphite electrodes.

High-power graphite electrodes are important smelting equipment in the metallurgical industry, and they play a vital role in electric arc furnaces. When purchasing and using high-power graphite electrodes, it is very important to understand the main technical parameters. Below we will introduce the main technical parameters of high-power graphite electrodes and their importance in detail.

1. Electrode diameter: Electrode diameter is one of the important parameters of high-power graphite electrodes. The size of the diameter directly affects the electrical conductivity and thermal conductivity of the electrode. Generally speaking, the larger the diameter, the stronger the electrical conductivity and thermal conductivity, which is suitable for high-power furnace operation. Therefore, when choosing a graphite electrode, choose a suitable diameter according to the required power size.

2. Electrode length: Electrode length is another important parameter. The selection of electrode length needs to take into account the size of the furnace and the process requirements. Under a certain power, the longer the electrode length, the stronger its conductivity and heat dissipation ability, which is suitable for high-power furnace operation. At the same time, the selection of electrode length will also affect production efficiency and the service life of the electrode.

3. Electrode density: Electrode density is an important parameter that affects the conductivity and thermal conductivity of the electrode. Generally, the higher the density of the graphite electrode, the stronger the conductivity and heat dissipation performance. Therefore, when selecting graphite electrodes, pay attention to its density level to ensure the stability and efficiency of furnace operation.

4. Electrode flexural strength and compressive strength: These two parameters are key indicators for measuring the strength and durability of graphite electrodes. In high-power furnace operation, the electrode needs to withstand greater thermal and mechanical stresses, so it is very important to have good flexural strength and compressive strength. Only with sufficient strength can the electrode ensure long-term stable operation.

5. Electrode thermal conductivity: Thermal conductivity refers to the thermal conductivity of the material under a unit temperature difference. For high-power graphite electrodes, the size of the thermal conductivity directly determines its ability to dissipate heat quickly. Graphite electrodes with high thermal conductivity can quickly dissipate the generated heat and effectively protect the electrodes from high temperature damage.

6. Wear resistance of electrodes: During furnace operation, the electrodes may be damaged due to friction and wear with the smelting materials. Therefore, the wear resistance of graphite electrodes is also an important technical parameter. When selecting electrodes, the hardness and wear resistance of the materials should be considered to extend the service life of the electrodes.

Graphite Electrode Current Carrying Capacity

| Nomina diameter |

RP |

HP |

UHP |

| Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

| in |

mm |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

| 12 |

300 |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

| 14 |

350 |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

| 16 |

400 |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

| 18 |

450 |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

| 20 |

500 |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

| 22 |

550 |

32000-40000 |

13-16 |

35000-55000 |

14-22 |

42000-64000 |

17-26 |

| 24 |

600 |

35000-41000 |

13-15 |

41000-61000 |

14-21 |

50000-73000 |

17-25 |

| 28 |

700 |

39000-48000 |

10-12 |

55000-82000 |

14-21 |

67000-99000 |

17-25 |

| 32 |

800 |

43000-54000 |

8-10 |

/ |

/ |

/ |

/ |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

FAQ

Q: Can you offer free samples?

A: Usually we can offer samples, if the sample is expensive, clients will pay the basic cost of the sample. We do not pay the freight for the samples. Before we received the first order, please afford the express fee. We will return the sample cost back to you within your first order.

Q: Do you accept OEM or ODM orders?

A: Sure, we do.

Q: How about your delivery time?

A: Usually our manufacture time is 7-10 days. And meanwhile it takes 7-30 days to apply the Import and export license for dual-useitems and technologies, so the delivery time is 7 to 30 days after payment.

Q: What is your MOQ?

A: There is no limit for MOQ, 1 ton is also available.

Q: What is the package like?

A: as customer's requested.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!