Graphite electrodes for melting arc furnace carbon electrode rod

What we offer

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

Is ultra-high power graphite electrode really worth investing in?

Ultra-high power graphite electrode is a new type of electrode material with excellent electrical conductivity and thermal stability. It is widely used in steel smelting, electrolytic aluminum production, magnetic drive and other fields. In current industrial production, the demand for graphite electrodes is increasing, and the market prospects are broad. Therefore, whether it is worthwhile to invest in ultra-high power graphite electrodes requires comprehensive consideration of many factors.

First of all, ultra-high power graphite electrodes have higher electrical conductivity, which can effectively reduce power consumption and improve production efficiency. In the process of steel smelting and electrolytic aluminum production, graphite electrodes can improve the energy efficiency of equipment, reduce production costs, and thus increase the profit margin of enterprises. In addition, graphite electrodes have a long service life, which can reduce the cost of equipment replacement, improve the utilization rate of equipment, and bring greater economic benefits to enterprises.

Secondly, ultra-high power graphite electrodes have good thermal stability, can withstand high temperatures and corrosion, and have a long service life. In high temperature environments, graphite electrodes are not easy to deform and ablate, and can maintain stable conductivity to ensure the normal operation of equipment. At the same time, graphite electrodes also have good antioxidant properties, which can extend the service life of equipment, reduce maintenance costs, and improve the stability and reliability of equipment.

Furthermore, with the continuous advancement of industrialization, the demand for electrode materials in industries such as steel and non-ferrous metals will continue to increase. Ultra-high power graphite electrodes have good performance advantages and production benefits, can meet the needs of different industries, and have great market potential and development space. Investing in ultra-high power graphite electrodes will hopefully obtain stable market demand and higher returns, bringing considerable economic benefits to investors.

Graphite Electrode Current Carrying Capacity

| Nomina diameter |

RP |

HP |

UHP |

| Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

| in |

mm |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

| 12 |

300 |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

| 14 |

350 |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

| 16 |

400 |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

| 18 |

450 |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

| 20 |

500 |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

| 22 |

550 |

32000-40000 |

13-16 |

35000-55000 |

14-22 |

42000-64000 |

17-26 |

| 24 |

600 |

35000-41000 |

13-15 |

41000-61000 |

14-21 |

50000-73000 |

17-25 |

| 28 |

700 |

39000-48000 |

10-12 |

55000-82000 |

14-21 |

67000-99000 |

17-25 |

| 32 |

800 |

43000-54000 |

8-10 |

/ |

/ |

/ |

/ |

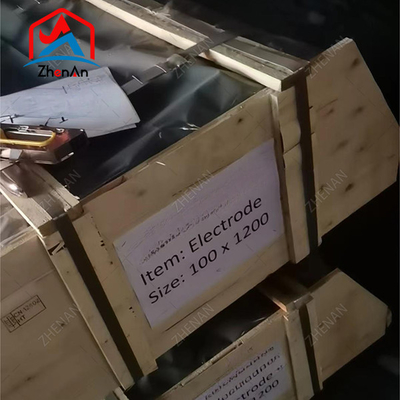

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

FAQ

Q: Can you offer free samples?

A: Usually we can offer samples, if the sample is expensive, clients will pay the basic cost of the sample. We do not pay the freight for the samples. Before we received the first order, please afford the express fee. We will return the sample cost back to you within your first order.

Q: Do you accept OEM or ODM orders?

A: Sure, we do.

Q: How about your delivery time?

A: Usually our manufacture time is 7-10 days. And meanwhile it takes 7-30 days to apply the Import and export license for dual-useitems and technologies, so the delivery time is 7 to 30 days after payment.

Q: What is your MOQ?

A: There is no limit for MOQ, 1 ton is also available.

Q: What is the package like?

A: as customer's requested.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!