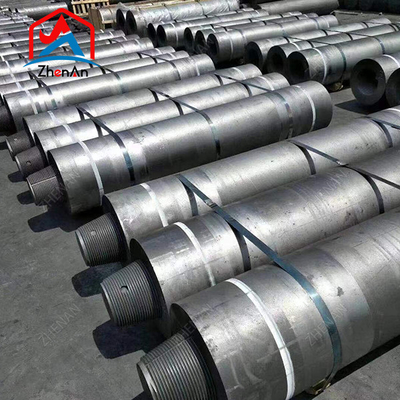

China Factory Manufacturer EAF Nipple 4TPIL Electrodo de grafito Graphite Electrode UHP 600*2400 mm

What we offer

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

How to judge whether the graphite electrode meets the high power standard?

Graphite electrode is a commonly used electrode material, which is widely used in electrochemical industry, metallurgical industry, chemical industry and other fields. In high power applications, the performance of graphite electrode has a vital impact on the equipment operation stability and production efficiency. Therefore, it is a very important issue to judge whether the graphite electrode meets the high power standard.

First of all, we need to understand the standard of high power graphite electrode. Generally speaking, the main performance indicators of high power graphite electrode include conductivity, mechanical properties, heat resistance and chemical corrosion resistance. Conductivity is a key indicator to measure the conductivity of electrode, which directly affects the rate and energy consumption of electrolysis reaction. Mechanical properties mainly include bending strength and tensile strength, which determine the durability of electrode under high power conditions. Heat resistance and chemical corrosion resistance determine the stability of electrode under high temperature and high corrosion environment.

What are the methods to judge whether the graphite electrode meets the high power standard?

In order to judge whether the graphite electrode meets the high power standard, we can take the following methods:

1. Conductivity test: judge its conductivity by measuring the conductivity of the electrode. Conductivity meters or resistance meters are usually used for testing to check whether the conductivity of the electrode meets the requirements under high power.

2. Mechanical performance test: Perform bending tests, tensile tests, etc. on the electrode to test its bending strength and tensile strength. By comparing the standard values, determine whether the mechanical properties of the electrode meet the high power standards.

3. Heat resistance test: Place the electrode in a high temperature environment to observe its thermal expansion performance and thermal stability. Detect whether the electrode breaks or deforms at high temperatures.

4. Chemical corrosion resistance test: Place the electrode in a chemically corrosive medium to detect its chemical corrosion resistance. Observe whether corrosion occurs on the electrode surface to determine whether the electrode meets the high power standard.

5. Simulation test in actual application: Place the graphite electrode in a simulated electrolytic cell for actual electrochemical reaction test to observe the working condition of the electrode under high power conditions. Through actual operation test, determine whether the electrode can meet the high power requirements.

In summary, judging whether a graphite electrode meets the high-power standard is a comprehensive process, which requires comprehensive testing and evaluation in terms of conductivity, mechanical properties, heat resistance, and chemical corrosion resistance. Only when all performance indicators meet the high-power standard requirements at the same time can the stable operation and reliability of the electrode under high-power conditions be ensured. Therefore, when selecting and using graphite electrodes, enterprises should focus on comprehensive evaluation and testing of electrode performance to ensure the normal operation of equipment and improve production efficiency.

Graphite Electrode Current Carrying Capacity

| Nomina diameter |

RP |

HP |

UHP |

| Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

| in |

mm |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

| 12 |

300 |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

| 14 |

350 |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

| 16 |

400 |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

| 18 |

450 |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

| 20 |

500 |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

| 22 |

550 |

32000-40000 |

13-16 |

35000-55000 |

14-22 |

42000-64000 |

17-26 |

| 24 |

600 |

35000-41000 |

13-15 |

41000-61000 |

14-21 |

50000-73000 |

17-25 |

| 28 |

700 |

39000-48000 |

10-12 |

55000-82000 |

14-21 |

67000-99000 |

17-25 |

| 32 |

800 |

43000-54000 |

8-10 |

/ |

/ |

/ |

/ |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer with our own factory, with an annual output of 550,000 tons of various refractory materials. We not only provide high quality products with the best price, but also the best pre-sale and after-sale service.

Q: What kind of products can you provide?

A: We can supply all kinds of refractory products, such as: refractory bricks, high alumina bricks, clay bricks, magnesium-carbon bricks, silicon carbide bricks, castables, graphite products, ceramic fiber products and so on.

Q: What are your main products?

A: Our company mainly produces graphite related products. We can provide customization according to the specific needs of customers.

Q: Are you a factory or trading company?

A: We’re factory and has the independent right of export and import.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!