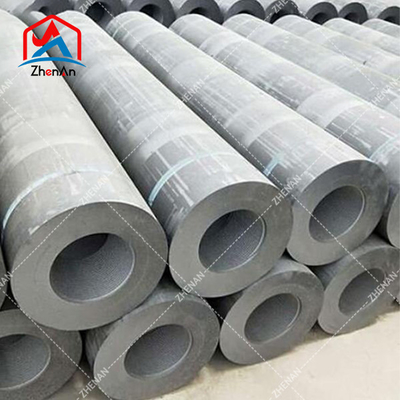

Electric arc furnace RP Hp UHP 600mm graphite electrodes High Conductivity

Our Services

1. We provide the best suitable products and solutions according to customer 's requirements.

2. We provide test report of the whole production process.

3. We provide safe, fast, preferential price transport scheme for customer.

4. We provide 24 hours after-sale service no matter when you contact us.

Will ultra-high power graphite electrodes become mainstream materials in the future?

Graphite electrodes are an important material widely used in industrial production processes, especially in electric furnaces for high-temperature and high-intensity electrolysis. Whether ultra-high power graphite electrodes will become mainstream materials in the future is a topic of great concern. This article will discuss this issue from the perspective of the development history, characteristics and application fields of graphite electrodes.

As a material with excellent conductivity and thermal stability, graphite electrodes are widely used in metal products, alloy production, and chemical industries. It is usually made of coke and natural graphite after high-temperature graphitization. It has high thermal conductivity and high oxidation resistance and can withstand the electrolysis process under high temperature. In an electric furnace, the main function of a graphite electrode is to release oxygen or chlorine in the electrolyte while transmitting current in order to convert the raw material into the desired product. Therefore, graphite electrodes play a vital role in the production process.

Whether ultra-high power graphite electrodes will become mainstream materials in the future depends on their performance and application field requirements. At present, with the continuous development of industrial production, the requirements for graphite electrodes are gradually increasing. Although traditional graphite electrodes have certain conductivity and thermal stability, their performance may no longer meet the needs in some high-power and high-temperature production environments. Therefore, people began to study and develop ultra-high power graphite electrodes to meet the growing industrial needs.

Compared with traditional graphite electrodes, ultra-high power graphite electrodes have higher electrical conductivity and thermal conductivity, can withstand higher current density and temperature, and have a longer service life. This makes ultra-high power graphite electrodes have broad application prospects in some fields with extremely high requirements for electrode performance. For example, in the aluminum electrolysis industry, electricity is required to have high strength, high conductivity, high heat resistance and other characteristics to ensure production efficiency and quality. Ultra-high power graphite electrodes can better meet these requirements and are more likely to become mainstream materials.

In addition to being used in traditional metal smelting and chemical industries, ultra-high power graphite electrodes also have broader application prospects. For example, in the field of new energy vehicles, the demand for high-performance battery materials is growing, and graphite electrodes, as an important component of batteries, have also received higher attention. Ultra-high power graphite electrodes can improve the charging and discharging efficiency and cycle life of batteries, thereby improving the performance of batteries. In this context, ultra-high power graphite electrodes are expected to become mainstream materials and promote the development of the new energy vehicle industry.

Graphite Electrode Current Carrying Capacity

| Nomina diameter |

RP |

HP |

UHP |

| Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

| in |

mm |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

| 12 |

300 |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

| 14 |

350 |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

| 16 |

400 |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

| 18 |

450 |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

| 20 |

500 |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

| 22 |

550 |

32000-40000 |

13-16 |

35000-55000 |

14-22 |

42000-64000 |

17-26 |

| 24 |

600 |

35000-41000 |

13-15 |

41000-61000 |

14-21 |

50000-73000 |

17-25 |

| 28 |

700 |

39000-48000 |

10-12 |

55000-82000 |

14-21 |

67000-99000 |

17-25 |

| 32 |

800 |

43000-54000 |

8-10 |

/ |

/ |

/ |

/ |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

RFQ

Q: Can I get some samples?

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

Q: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q: What's the lead time?

A: According to the order quantity, small order usually need 3-5 days, big order need negotiation.

Q: What's your payment terms?

A: We receive Escrow, T/T, West Union, Cash and etc

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer with our own factory, with an annual output of 550,000 tons of various refractory materials. We not only provide high quality products with the best price, but also the best pre-sale and after-sale service.

Q: What kind of products can you provide?

A: We can supply all kinds of refractory products, such as: refractory bricks, high alumina bricks, clay bricks, magnesium-carbon bricks, silicon carbide bricks, castables, graphite products, ceramic fiber products and so on.

Q: What are your main products?

A: Our company mainly produces graphite related products. We can provide customization according to the specific needs of customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!