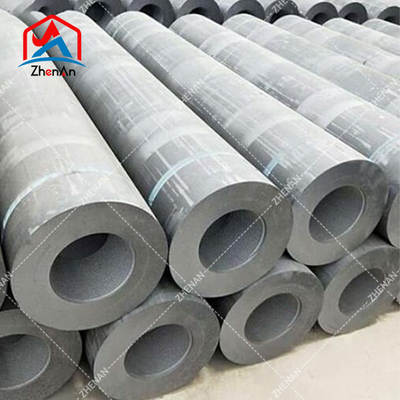

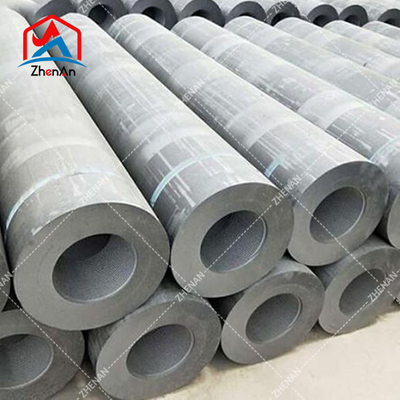

Wholesale 200mm 300mm 400mm RP Hp UHP graphite electrode for steel making

Our Services

1. We provide the best suitable products and solutions according to customer 's requirements.

2. We provide test report of the whole production process.

3. We provide safe, fast, preferential price transport scheme for customer.

4. We provide 24 hours after-sale service no matter when you contact us.

What factors affect the cost-effectiveness of ultra-high power graphite electrodes?

The cost-effectiveness of ultra-high power graphite electrodes is affected by many factors. The following are some of the main factors:

1. Raw material cost: The main raw materials in the manufacturing process of graphite electrodes are natural graphite, coke and binders. Raw materials with large price fluctuations will directly affect the cost-effectiveness of graphite electrodes.

2. Energy cost: The production process of graphite electrodes requires a lot of energy, including electricity and gas. Fluctuations in energy prices will have an impact on the production cost of graphite electrodes.

3. Production process and technical level: The production process of ultra-high power graphite electrodes requires sophisticated technology and mature production technology. Improving production technology and technical level can reduce production costs and improve cost-effectiveness.

4. Labor cost: The production process of graphite electrodes requires a large number of laborers, including operators, technicians and managers. Fluctuations in labor costs will affect the production cost of graphite electrodes.

5. Competition: The graphite electrode market is highly competitive and the market price fluctuates greatly. To achieve cost-effectiveness in a highly competitive market, it is necessary to continuously improve product quality and reduce production costs.

6. Policies and regulations: Government policies and regulations on environmental protection, energy consumption, etc. will also affect the production cost of graphite electrodes. Production methods that comply with policies and regulations can reduce production costs and improve cost-effectiveness.

7. Supply and demand relationship: The supply and demand relationship of graphite electrodes will also affect the price and cost-effectiveness of products. Oversupply in the market will lead to a drop in product prices, thereby affecting cost-effectiveness.

In general, the cost-effectiveness of ultra-high power graphite electrodes is affected by many factors. Only when the price of raw materials is stable, the energy cost is low, the technology and process level are improved, the labor cost is reasonable, the competition is fierce, the policy and regulatory support, and the balance of supply and demand are taken into consideration, can the maximum cost-effectiveness be achieved. In order to improve the competitiveness and market share of products, manufacturers need to continuously optimize the production process, reduce production costs, improve product quality and meet market demand.

Graphite Electrode Current Carrying Capacity

| Nomina diameter |

RP |

HP |

UHP |

| Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

| in |

mm |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

| 12 |

300 |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

| 14 |

350 |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

| 16 |

400 |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

| 18 |

450 |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

| 20 |

500 |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

| 22 |

550 |

32000-40000 |

13-16 |

35000-55000 |

14-22 |

42000-64000 |

17-26 |

| 24 |

600 |

35000-41000 |

13-15 |

41000-61000 |

14-21 |

50000-73000 |

17-25 |

| 28 |

700 |

39000-48000 |

10-12 |

55000-82000 |

14-21 |

67000-99000 |

17-25 |

| 32 |

800 |

43000-54000 |

8-10 |

/ |

/ |

/ |

/ |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

ZhenAn International Co., Limited. is located in Anyang City, Henan Province, the hometown of Oracle. The company specializes in the research and development, production and sales, and international trade of graphite electrodes and carbon products. It has nearly 30 years of experience in graphite electrode production and research and development and independent intellectual property rights. It is a domestic professional production and research and development enterprise with excellent quality, complete varieties and multiple specifications. Its products enjoy a high reputation at home and abroad.

RFQ

Q: Can I get some samples?

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

Q: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q: What's the lead time?

A: According to the order quantity, small order usually need 3-5 days, big order need negotiation.

Q: What's your payment terms?

A: We receive Escrow, T/T, West Union, Cash and etc

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer with our own factory, with an annual output of 550,000 tons of various refractory materials. We not only provide high quality products with the best price, but also the best pre-sale and after-sale service.

Q: What kind of products can you provide?

A: We can supply all kinds of refractory products, such as: refractory bricks, high alumina bricks, clay bricks, magnesium-carbon bricks, silicon carbide bricks, castables, graphite products, ceramic fiber products and so on.

Q: What are your main products?

A: Our company mainly produces graphite related products. We can provide customization according to the specific needs of customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!