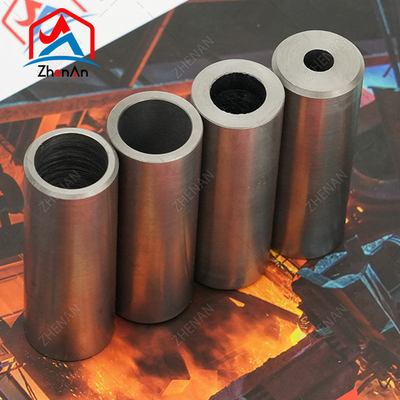

W75cu25 Tungsten Copper Alloy Tube for Industry Application

Description:

How to melt tungsten copper tubes?

Melting tungsten copper tubes is a process whose main purpose is to melt tungsten and copper into a uniform alloy in a certain proportion. Let me introduce the method of melting tungsten copper tubes.

First, prepare the raw materials required for melting tungsten copper tubes, namely tungsten and copper. Since the melting points of tungsten and copper are quite different, auxiliary agents are needed to lower the melting point of tungsten. Common auxiliary agents include nickel, iron, etc.

Secondly, put the tungsten and copper mixed in a certain proportion into the melting furnace. Add an appropriate amount of auxiliary agent into the melting furnace to lower the melting point of tungsten so that it can be fully fused with copper.

Next, ignite the melting furnace to gradually increase the temperature inside it. Generally speaking, the melting point of tungsten is about 3410°C, while the melting point of copper is about 1083°C, so the temperature needs to be controlled above the melting point of tungsten. During the heating process, the temperature inside the melting furnace should be kept uniform to ensure that tungsten and copper are fully mixed.

When the temperature in the melting furnace reaches the requirement, tungsten and copper begin to melt and mix with each other. At this time, the temperature and pressure inside the melting furnace need to be controlled to ensure that tungsten and copper can be fully mixed and the influence of gas or oxides is excluded.

Finally, the smelted tungsten-copper alloy is cooled and processed into tubular products. During the cooling process, the microstructure of the alloy should be ensured to ensure the quality of the tubular products.

In general, smelting tungsten copper tubes requires mixing tungsten and copper in a certain proportion and adding an appropriate amount of auxiliary agent. At the same time, the temperature and pressure inside the furnace are controlled to ensure that tungsten and copper can be fully mixed. Finally, it is cooled and processed to make a finished product. This is the basic method of smelting tungsten copper tubes.

Specifications:

| Product Name |

Tungsten tube |

| Grade |

WAL1,WAL2,WAL3,W1,W2 |

| Surface Treatment |

Polished, Forged, Straightening |

| Purity |

≥99.95% |

| Density |

≥18.6g/cm3 |

| Standard |

GB4188-84, GB/T4187-2006 or customer’s request |

| Size |

wall thickness:0.3~8mm ,out diameter 5~200mm * Length 2000mm max OR As yours |

| Application |

Tungsten steel

Industry base carbide

Hot strong and durable alloys

Contactor material and high proportion alloy

Electric vacuum of tungsten lighting material

Tungsten compounds

|

Packing & Delivery:

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Our inspection equipment:

FAQ:

Q: Are you a factory or a trading company?

A: We are factories and trading company.

Q: Can I have my own LOGO on the product?

A: Yes, you can send us your design and we can make your LOGO.

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: Can we visit your factory ?

A: Warmly welcome once we have your schedule we will pick you up .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!