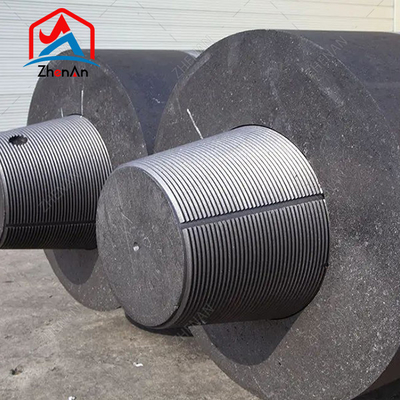

Ultra-High-Power UHP700 UHP600 HP450 RP150 Graphite Electrode Used in Steel Making

The key characteristics of ultra-high-power graphite electrodes are:

High Thermal Conductivity: Ultra-high-power graphite electrodes have high thermal conductivity, allowing them to resist high temperatures during steel production.

High Electrical Conductivity: Ultra-high-power graphite electrodes have high electrical conductivity, enabling them to conduct high currents during steel production.

Low Resistance: Ultra-high-power graphite electrodes have low resistance, helping to minimize energy losses during steel production.

Low Thermal Expansion Coefficient: Ultra-high-power graphite electrodes have a low thermal expansion coefficient, making them less susceptible to thermal shock and cracking.

High Mechanical Strength: Ultra-high-power graphite electrodes have high mechanical strength, able to withstand the physical stresses of the steel-making process.

High Chemical Resistance: Ultra-high-power graphite electrodes have high chemical resistance, resisting corrosion and erosion from chemicals encountered during steel production.

HP Graphite Electrode

| Items |

Specific Electric Resistance <= µΩ·m |

Flexural Strength >=MPa |

MOE<= GPa |

CTE( 100-600ºC) <= 10-6/ºC |

ASH<= |

DIAMETER AND LENGTH |

Bulk density >=g/cm3 |

Needle Coke Content

% |

| Standard ( YB/T 4089-2015 ) |

E |

5.2-6.5 |

10.5-15 |

9-12 |

1.5-2.2 |

0.2 |

200mm-700mm

1800mm-2700mm |

1.66-1.72 |

20-35% |

| N |

4.0-4.5 |

20-26 |

14-18 |

1.2-1.5 |

1.75-1.82 |

| Factory Supply |

E |

<=6.5 |

10.5-15 |

9-12 |

1.5 |

0.2 |

>=1.66 |

25%-40% |

| N |

<=4.0 |

20-26 |

14-20 |

1.2 |

>=1.78 |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

zhenAn has been in the business of ferroalloy for 30 years now. It is a leading manufacturer and supplier of ferro silicon,silicon manganese,silicon metal,silicon carbide,high carbon silicon and so on.our company is a large-sized production enterprise integrating research, development, production and sales.

Our company locates in Anyang city,Henan province of China a total area of about 15,000 square.With many years growing and developing,our company has domestic advanced smelting furnaces,crushing and screening production lines with annual output of 20000 tons.At the some time has two laboratories and a metallurgical materials testing center with dozens of senior researchers.The products are supplied to many large and medium-sized iron and steel enterprises in China, and exported to Japan, Korea, India, Europe and the United States.

FAQ

Q: Where can I get product and price information?

A: Send us inquiry e-mail, we will contact with you when we receive your email,or contact me on chat app.

Q: What is the term of the delivery?

A: FOB, CFR, CIF, etc.

Q: How to delivery the goods?

A: We deliver the goods by truck to port, or loading in container in factory.

Q: Are you trading company or factory?

A: We are direct factory and have the most advanced machine and about 200 employee in our 30000m2 workshop.

Q: What's the delivery time?

A: 2-3 weeks after got the deposit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!