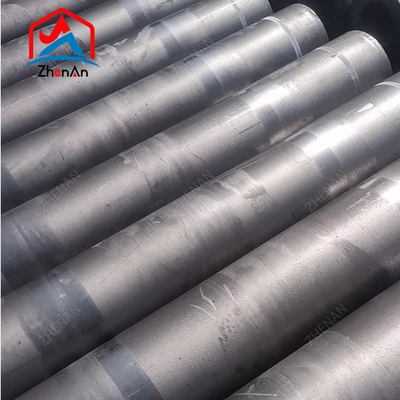

Dia 75mm-700mm L1800-2700mm UHP HP RP Grade Eaf Graphite Electrode

Applications of Graphite Electrodes

Metallurgy Industry: Graphite electrodes are widely used in the metallurgy industry. In steel smelting, graphite electrodes serve as electrodes in electric arc furnaces, providing stable current transmission under high-temperature and high-pressure environments. Additionally, they are extensively used in the production of metallurgical materials such as silicon-manganese alloys and ferrosilicon.

Chemical Industry: Graphite electrodes are primarily utilized in the chemical industry for the production of fluorides, chlorides, alumina, and other chemical materials. These chemicals are often manufactured in high-temperature and high-pressure environments, where graphite electrodes can withstand such extreme conditions, ensuring high efficiency and safety in chemical production.

Power Industry: Graphite electrodes have extensive applications in the power industry. In the power generation process, they are used as cathode materials for electrolytic preparation of metals such as copper and aluminum. Additionally, graphite electrodes are essential structural materials in nuclear reactors.

UHP Graphite Electrode

| Physical and Chemical Index of UHP |

|

Items

|

unit

|

Diameter: 200-700mm |

| Standard |

Test data |

| Electrode |

Nipple |

Electrode |

Nipple |

| Electrical resistance |

μΩm |

5.5-6.0 |

5.0 |

5.0-5.8 |

4.5 |

| Flexure strength |

Mpa |

9.5 |

15 |

13-15 |

17-19 |

| Modulus of elasticity |

GPa |

14 |

18 |

12 |

14 |

| Ash content |

% |

0.2 |

0.2 |

0.2 |

0.2 |

| Apparent density |

g/cm3 |

1.64-1.68 |

1.70-1.72 |

1.68-1.72 |

1.78 |

| Factor of expansion(100-600ºC) |

x10-6/ºC |

2.0 |

1.7 |

1.5 |

1.4 |

Packing & Delivery

REMARK: the above data is just on standard of YB/T, the actual product is big different from the above. For the actual, be free to contact us, please.

Service: We can supply you with free samples, a booklet, a laboratory test report, an Industry Report, etc.

Welcome to our factory and company for a visit!

Company profile

zhenAn has been in the business of ferroalloy for 30 years now. It is a leading manufacturer and supplier of ferro silicon,silicon manganese,silicon metal,silicon carbide,high carbon silicon and so on.our company is a large-sized production enterprise integrating research, development, production and sales.

Our company locates in Anyang city,Henan province of China a total area of about 15,000 square.With many years growing and developing,our company has domestic advanced smelting furnaces,crushing and screening production lines with annual output of 20000 tons.At the some time has two laboratories and a metallurgical materials testing center with dozens of senior researchers.The products are supplied to many large and medium-sized iron and steel enterprises in China, and exported to Japan, Korea, India, Europe and the United States.

FAQ

Q: Where can I get product and price information?

A: Send us inquiry e-mail, we will contact with you when we receive your email,or contact me on chat app.

Q: What is the term of the delivery?

A: FOB, CFR, CIF, etc.

Q: How to delivery the goods?

A: We deliver the goods by truck to port, or loading in container in factory.

Q: Are you trading company or factory?

A: We are direct factory and have the most advanced machine and about 200 employee in our 30000m2 workshop.

Q: What's the delivery time?

A: 2-3 weeks after got the deposit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!