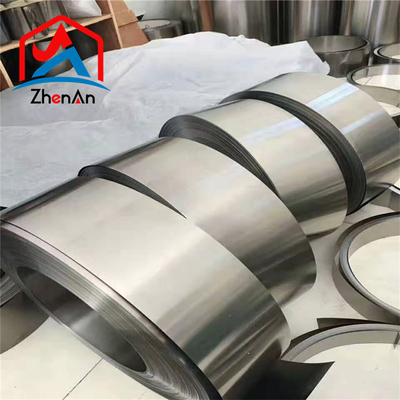

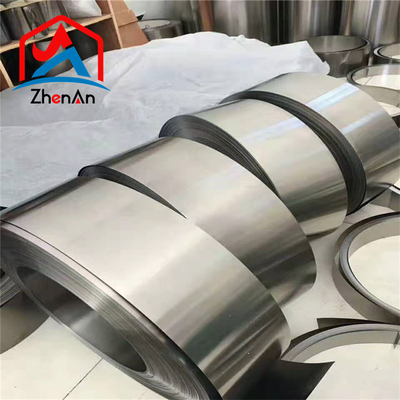

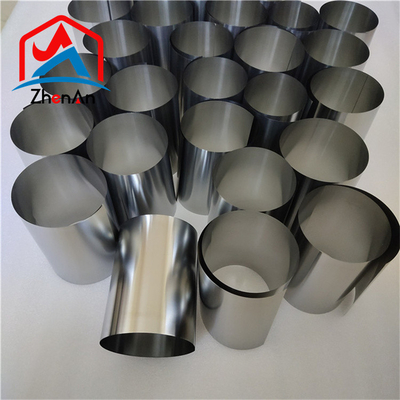

Molybdenum Foil, Thickness 0.025mm, 99.9%

Description:

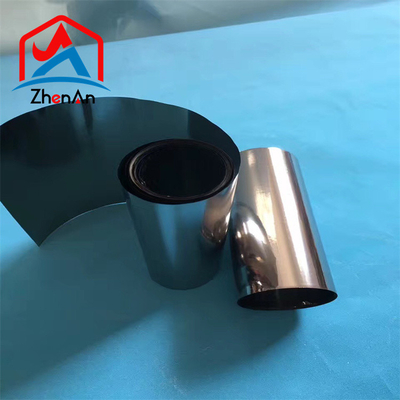

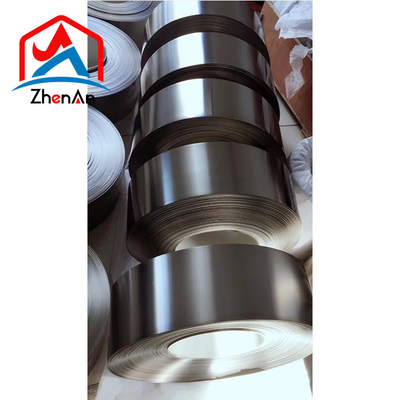

Moly Foil is a molybdenum product, which is a thin sheet composed of transition metal molybdenum (Mo) and rare earth elements. The purity is usually greater than 99.95%, the thickness is 0.025-0.09mm, the width is 30-100mm, the length is greater than 200mm, and the surface state is Alkaline pickled surface, annealed condition and polished surface.

Specifications:

| Product name |

0.1mm thickness Molybdenum foil |

| material |

Mo 1 |

| purity |

99.95% min |

| dimension |

0.1x100x150mm |

| process |

cold rolling |

| thickness |

from 0.05 to 2mm |

| features |

High purity and density, good performances of high strength, uniform internal organization and good resistance to high temperature creep |

| test and quality |

size,appearance,process performance,mechanical properties |

| remarks |

We can provide customized products according to the drawing. |

From the perspective of physical and chemical properties, Moly Foil is a silver-gray metal sheet with metallic luster, melting point is about 2620 ℃, boiling point is about 5560 ℃, relative density is 10.2g/cm3, has high hardness and low thermal expansion coefficient , high thermal conductivity, small resistivity, good chemical stability and electrochemical performance. It does not react with air or water under normal temperature and pressure, but it will be slowly oxidized under heating conditions.

From the production method point of view, the preparation steps of Moly Foil are: first use medium-grained molybdenum powder as raw material, and obtain the molybdenum compact through cold isostatic pressing, and then undergo composite sintering, low-temperature large deformation billet opening, low-temperature cross-hot rolling, After alkali cleaning, grinding and shearing, followed by warm rolling, hydrogen annealing, surface cleaning and shearing, cross cold rolling, surface degreasing, and finally vacuum stress relief annealing and cutting inspection, the required products can be obtained.

FAQ:

Q1. Are you the factory or the trading company?

A1. We are the direct-sale factory with our own trading company. Our factory has 20 years experience in the filed of alloy products.

Q2. What's your main products?

A2. Our main products are all kinds of alloy materials for foundry and casting industry, including ferro silicon magnesium (rare earth magnesium alloy), ferro silicon, ferro manganese, silicon manganese alloy, silicon carbide, ferro chrome and cast iron, etc.

Q3. How can you guarantee the quality?

A3. We have the most professional workers for production and testing of the products, most advanced production equipment and testing equipment. For every batch of products, we will test the chemical composition and to make sure it can reach the quality standard that customers required before they are dispatched to the customers.

Q4. Can I get sample from you for checking the quality?

A4. Yes, we can provide free samples to customers for them to check the quality or do the chemical analyses, but please tell us the detailed requirement for us to prepare the right samples.

Q5. What's your MOQ? Can I buy a container with different products mixed?

A5. Our MOQ is one 20 feet container, about 25-27 tons. You can buy different products in a container mixed, it is usually for trial order and we hope that can buy 1 or 2 products in a full container in future after you testing our products are good quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!