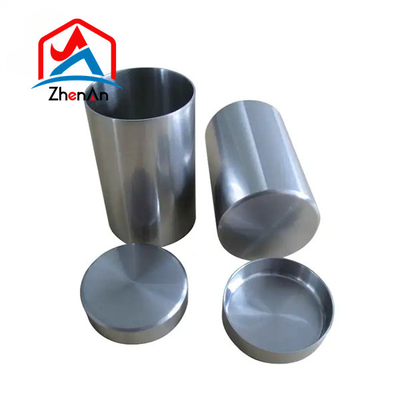

Tungsten Alloy Crucible

Description:

Tungsten crucible is formed by turning and welding tungsten rods. It is made of pure tungsten plates, tungsten sheets and pure tungsten rods through corresponding processes. There are many preparation methods. It is widely used in rare earth smelting, quartz glass, crystal growth and other industries, and plays a major role in modern industry.

Specifications:

| Product |

Tungsten Crucible |

| Purity |

Process |

| Process |

Sintering or machining from tungsten rod |

| Surface |

Grinding, Finish turning |

Application:

1. Isostatic pressing-sintering method

2. Forging processing method

3. Chemical vapor deposition method

4. Plasma spray forming method

5. Spin forming method

6. Riveting forming method

Among these six preparation methods, three are most commonly used: isostatic pressing-sintering method, forging processing method and riveting forming method. Most products are made by these three methods. Another chemical vapor deposition method can prepare high-purity, dense, and large-sized products, making people full of expectations for its future development.

AbThe isostatic pressing-sintering method mainly includes six processes: raw material batching, powder loading, isostatic pressing, high-temperature sintering, turning, and finished product inspection. The steps are as follows: Assemble the mold according to the size of the blank charging requirements, load the tungsten powder raw material that meets the national standard requirements into the mold and seal it, put it into a cold isostatic press for pressing, the forming pressure is generally 180~250 MPa, and then press The billet is placed in a high-temperature induction sintering furnace for sintering. The heating rate is 80~150℃/h, the maximum temperature is 2200~2400℃, and the high temperature holding time is 4~8 h. The sintered billet is processed according to the requirements of the finished product, and finally the finished product is Conduct quality inspections such as appearance, size, density, etc.

FAQ:

Q: Can I get samples before order ?

A: Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

Q: How to guarantee quality?

A: Always a pre-production sample before mass production;Always final Inspection before shipment.

Q: Why choose us?

A: We have Experienced staffs;Provide kinds of certificates;The content packing particle size may be based on customer demand;Quality can be guaranteed. we provide safe products to our users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!