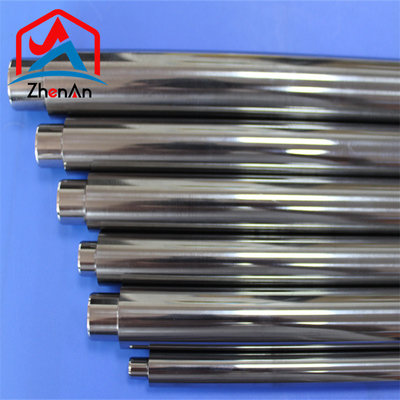

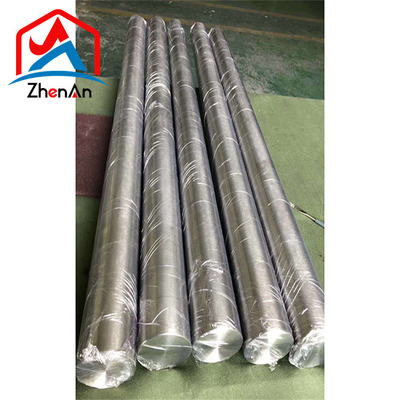

Pure Molybdenum Tzm Bar ASTM B386

Description:

For the welding of Molybdenum TZM Rod, commonly used methods include arc welding, electron beam welding, laser welding and plasma welding.

Specifications:

CHEMICAL COMPOSITION OF TZM ROD

| Ti |

Mo |

Zr |

C |

| 0.5 |

99.40 |

0.08 |

0.02 |

MECHANICAL COMPOSITION OF TZM ROD

| Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation L = 5 D % |

| 965 MPa, 140000 psi |

860 MPa , 125000 psi |

6 – 10 |

Application:

Choose the appropriate welding method: For the welding of TZM alloy rods, commonly used methods include arc welding, electron beam welding, laser welding and plasma welding. According to the specific situation, choose the appropriate welding method to achieve good welding results.

Pre-treatment and cleaning: Before welding, it is key to perform the necessary pre-treatment and cleaning of the TZM alloy rod. Surface oxides, grease, and contaminants will affect the quality and strength of the weld, so they should be cleaned using appropriate methods, such as mechanical cleaning, solvent cleaning, or electrolytic cleaning.

Welding material selection: Selecting the appropriate welding material is also important. Commonly used welding materials include TZM alloy welding wire, pure molybdenum welding wire, etc. Make sure the welding material matches the composition of the TZM alloy rod to avoid adverse chemical reactions or uneven welds.

Control welding parameters: Parameter control during welding is crucial to obtain good welding results. The selection and control of parameters including welding current, welding speed, preheating temperature and post-heat treatment can affect the quality of the weld and the heat-affected zone (HAZ) of the welding area.

Carry out post-weld treatment: After welding is completed, proper post-weld treatment can help eliminate residual stress and improve the strength of the weld. Common post-weld treatments include annealing, heat treatment and heat drawing.

FAQ:

Q : How can you control your quality?

A : For each production processing, ZhenAn have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q: Are you a manufacture or trader?

A: Both, we not only can provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

Q : Do you provide free samples?

A : Of course, free samples are available.

Q: What is your lead time?

A : It usually needs about 15- 20 days after receiving the PO.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!